Rotary hook position is wrong & needle broken

Release time:2021-04-14 15:09:48

Fault: Rotary hook is on wrong position, needle broken

Solutions:

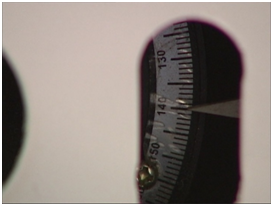

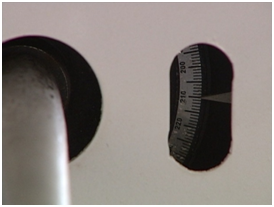

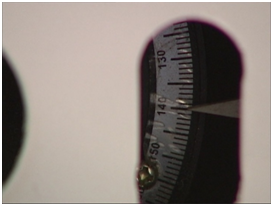

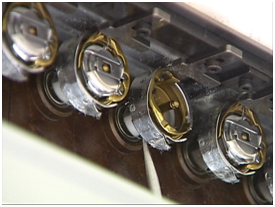

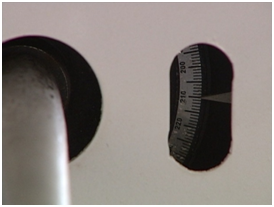

1. Turn the dial to 70 degrees and loosen the screw

2 Turn the dial to 140 degrees and loosen the second screw

3 Turn the dial to 210 degrees and loosen the third screw

4 Pull down the needle bar

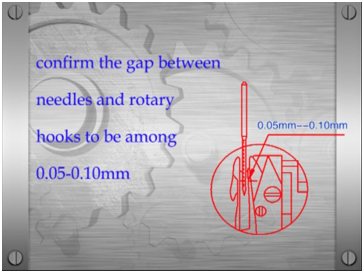

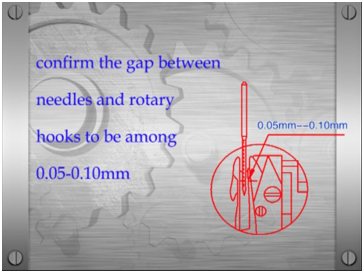

5 Make the gap between the hook tip and the needle hole 0.05 to 0.10mm.

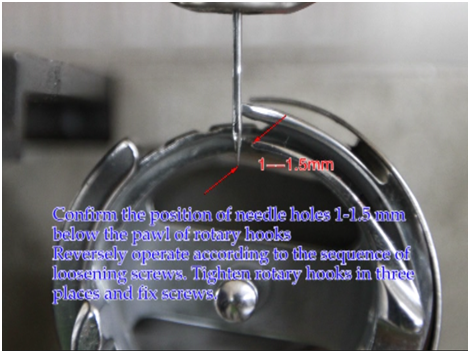

6 Make the needle hole position 1-1.5 mm lower than the hook claw. Make the position of needle hole 1-1.5mm below the pawl of rotary hook.